Newsletter Subscribe

Enter your email address below and subscribe to our newsletter

Enter your email address below and subscribe to our newsletter

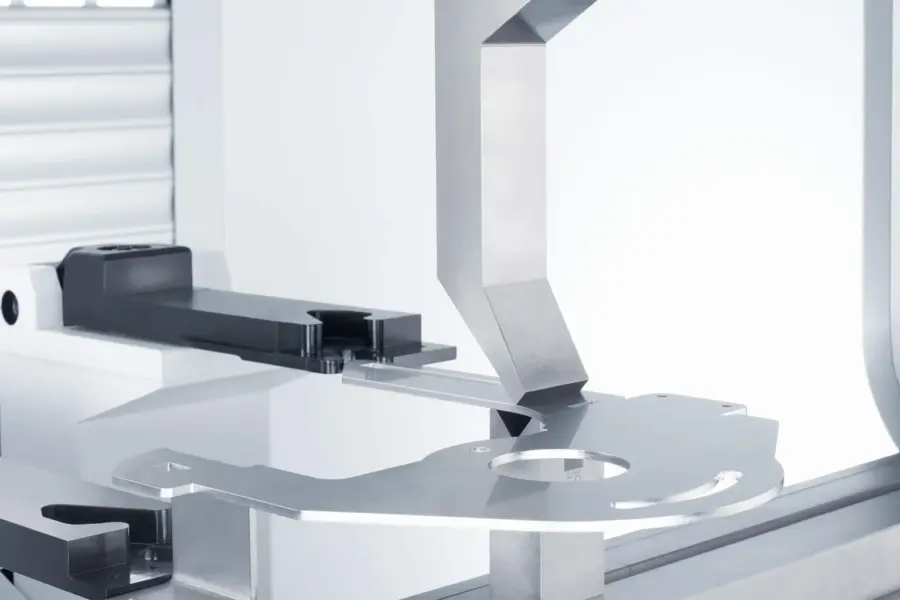

Modern bending technology continues to evolve, and few examples illustrate this progress better than the machines from TRUMPF’s bending portfolio. This press brake photo gallery brings together a curated selection of machine action shots and video highlights inspired by TRUMPF’s…

As the editor-in-chief of PressBrakeGuide.com, I’ve had the privilege of walking countless factory floors, from bustling high-volume production lines to meticulous aerospace job shops. I’ve seen these incredible machines evolve from simple, manually-operated hydraulic workhorses into the hyper-precise, automated bending…

Understanding how a press brake works is one of the most essential foundations in modern sheet metal fabrication. Whether you are an operator learning the basics, an engineer improving production processes, or a factory owner comparing different bending technologies, the…

The automotive industry relies on a complex network of metal-forming processes to transform flat sheet materials into structural components capable of withstanding extreme loads, vibrations, and crash forces. Among all forming technologies used on today’s production lines, the press brake…

Setting up a press brake for the first time is both exciting and intimidating. Although modern CNC press brakes automate many steps, the quality of a bend still depends on how well the machine, tooling, and material are prepared before…

Operating a CNC press brake for the first time can feel overwhelming. The control screen is filled with unfamiliar icons, the machine has multiple moving components, and every bending parameter seems important enough to make or break the final part.…

Press brake types form the fundamental basis for understanding modern sheet metal bending technology. Mechanical, hydraulic, and electric press brakes each evolved from different technological eras, yet they coexist today because every bending application—whether precision, productivity, energy efficiency, or heavy-tonnage…

Among all sheet-metal fabrication machines, the press brake holds a unique position. It is one of the oldest, most versatile, and most essential tools in any fabrication environment—from small family-run workshops to multinational OEM factories. Whether working with simple brackets…

Over the past decade, the sheet metal fabrication industry has undergone a fundamental transformation, driven largely by the rapid evolution of CNC press brake controllers. While mechanical frames, hydraulic systems, and tooling remain essential foundations of a bending machine, the…

In the last decade, the global sheet-metal fabrication industry has undergone a profound transformation. As factories shift toward digital production and Industrie 4.0 standards, traditional press brake operations—once heavily dependent on manual skill—are now becoming automated, data-driven, and highly intelligent.…