Assine nossa newsletter

Insira seu endereço de e-mail abaixo e inscreva-se em nossa newsletter.

Insira seu endereço de e-mail abaixo e inscreva-se em nossa newsletter.

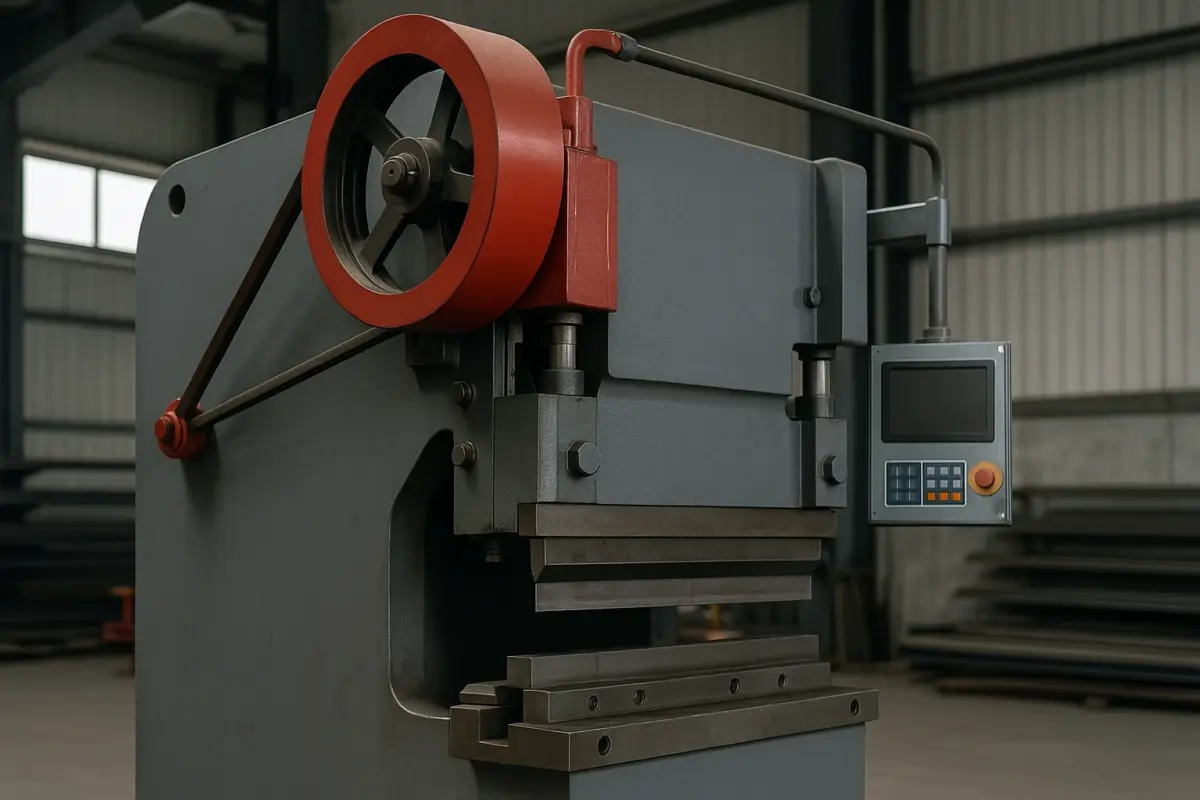

Os tipos de prensas dobradeiras formam a base fundamental para a compreensão da tecnologia moderna de dobra de chapas metálicas. Prensas dobradeiras mecânicas, hidráulicas e elétricas evoluíram em diferentes eras tecnológicas, mas coexistem hoje porque cada aplicação de dobra — seja precisão, produtividade, eficiência energética ou conformação de grandes tonelagens — exige uma arquitetura de máquina específica. Tanto para iniciantes quanto para profissionais, comparar esses tipos de prensas é essencial. Pressione o freio A escolha do tipo de máquina é crucial para selecionar a máquina correta, otimizar os custos de produção e melhorar a confiabilidade a longo prazo.

Este guia explica os princípios de funcionamento, as estruturas internas, as características de desempenho, as vantagens, as limitações e as aplicações ideais de todos os principais dispositivos. Pressione o freio Este artigo aborda diversos tipos de prensas dobradeiras, com base em longa experiência industrial, esclarecendo como cada tipo influencia a precisão da dobra, a repetibilidade, a leitura total do indicador (TIR), a estabilidade do pistão e a compatibilidade das ferramentas. Em vez de categorizar essas máquinas de forma simples, o artigo se concentra em seu comportamento operacional: como o pistão se move, como a pressão é aplicada, como a deformação é controlada e como a tecnologia aprimora o processo com a automação.

Escolher o tipo certo de prensa dobradeira não se resume apenas à categoria da máquina. Reflete uma compreensão mais profunda da dinâmica de dobra — aplicação de força, controle de movimento, arquitetura de segurança e consumo de energia. O setor evoluiu de mecanismos puramente mecânicos para sistemas servoelétricos avançados, mas nenhum tipo é universalmente superior. Cada um oferece vantagens que se adequam a ambientes de fabricação específicos.

As primeiras fábricas dependiam fortemente de prensas dobradeiras mecânicas movidas por grandes volantes, acionados por motores ou pedais. Essas máquinas dominaram a manufatura global por décadas devido à sua construção simples, alta velocidade de curso e fácil manutenção. No entanto, à medida que as especificações para dobras de precisão se tornaram mais rigorosas, as prensas dobradeiras hidráulicas surgiram como uma alternativa mais flexível e com força estável, permitindo controle CNC, batentes traseiros programáveis e pressão consistente ao longo do curso de dobra.

Na última década, as prensas dobradeiras elétricas ganharam popularidade devido aos seus servomotores extremamente precisos, baixo consumo de energia e operação limpa e silenciosa. Sua presença é especialmente dominante na fabricação de peças pequenas e chapas finas, onde a repetibilidade e a velocidade são mais importantes do que a capacidade de produção. Compreender como essas três gerações se comparam fornece uma base estrutural para a seleção de equipamentos.

As prensas dobradeiras não se limitam a dobrar metal; elas moldam o fluxo de trabalho de toda uma fábrica. O tipo de máquina escolhido determina a velocidade de produção, a taxa de refugo, os requisitos de habilidade do operador, as contas de energia e até mesmo os protocolos de segurança. As prensas dobradeiras mecânicas se destacam na produção contínua de alto volume, onde a velocidade é a prioridade. Os sistemas hidráulicos oferecem a flexibilidade necessária para fábricas com múltiplos produtos e materiais mais espessos. As máquinas elétricas têm o melhor desempenho em ambientes onde a precisão em nível micrométrico, a redução de ruído e a sustentabilidade ambiental são essenciais.

As diferenças tornam-se especialmente significativas ao lidar com materiais especiais, como aço inoxidável, ligas aeroespaciais e aço de alta resistência, onde o comportamento de retorno elástico é mais imprevisível. Certos tipos de prensas dobradeiras compensam melhor essas flutuações, afetando diretamente a consistência do produto.

Em vez de apresentar uma simples comparação tabular, este guia explica o comportamento de cada sistema em cenários reais de flexão. Por exemplo, as máquinas mecânicas dependem do momento do volante, o que proporciona alta velocidade, mas pouca adaptabilidade. As máquinas hidráulicas regulam a pressão por meio do controle do fluido, permitindo que o movimento do pistão se ajuste dinamicamente durante a flexão. As máquinas elétricas utilizam servomotores para gerar força linear, possibilitando o posicionamento ultrapreciso do pistão na ordem de micrômetros.

Essas diferenças afetam não apenas a precisão da dobra, mas também a forma como os operadores programam a máquina, reagem a geometrias complexas e mantêm a estabilidade a longo prazo.

As prensas dobradeiras mecânicas representam a forma mais antiga de tecnologia de dobra industrial. Embora os modelos mais modernos dominem as fábricas atuais, os sistemas mecânicos continuam relevantes devido à sua simplicidade e durabilidade. Muitas oficinas ainda utilizam esses equipamentos, principalmente para trabalhos repetitivos que exigem velocidade constante em vez da versatilidade das máquinas CNC.

As prensas dobradeiras mecânicas operam através de um volante sistema alimentado por um motor elétrico. Quando o operador aciona a embreagem, a energia rotacional é transferida do volante para o cambota, convertendo o movimento circular no movimento linear descendente do pistão. Esse mecanismo torna as prensas dobradeiras mecânicas extremamente rápidas, mas sua potência é fixa — o que significa que a máquina exerce força máxima na parte inferior do curso, independentemente da necessidade de dobra.

Essa característica leva a dois comportamentos principais: profundidade de curvatura previsível e capacidade limitada de modular a força durante o curso. Para curvaturas simples, essa previsibilidade é uma vantagem. Para peças complexas que exigem controle preciso do ângulo ou compensação ativa, torna-se uma limitação.

O coração de uma prensa dobradeira mecânica reside em seu virabrequim, braços Pitman, volante, embreagem e sistema de freio. Quando acionado, o virabrequim empurra o pistão para baixo em um arco suave e rápido. Como o movimento é derivado de uma ligação mecânica em vez de controle hidráulico ou servo, a máquina não consegue parar no meio do curso com a mesma precisão que os sistemas hidráulicos ou elétricos.

Isso afeta tanto a segurança quanto a flexibilidade. Os operadores precisam confiar em proteções mecânicas e sistemas de frenagem bem sincronizados para evitar o sobrecurso acidental. Além disso, as prensas dobradeiras mecânicas têm um curso fixo, o que as torna menos adaptáveis a geometrias de peças variadas.

Os sistemas mecânicos se destacam pela velocidade. Suas altas taxas de ciclo os tornam ideais para a dobra repetitiva de grandes volumes de materiais finos. Fábricas que produzem componentes simples — suportes, perfis, painéis de ar condicionado, caixas elétricas — frequentemente se beneficiam do rápido movimento de subida e descida proporcionado pelas prensas dobradeiras mecânicas.

Em termos de manutenção, as prensas dobradeiras mecânicas possuem menos componentes que se degradam com a pressão ou a temperatura, resultando em uma longa vida útil sob cargas de produção constantes. Seu projeto favorece uma operação previsível, o que é valioso em oficinas com operadores menos qualificados em CNC.

As prensas dobradeiras mecânicas não possuem a capacidade de ajustar dinamicamente a posição do pistão durante a dobra. A compensação do retorno elástico, a correção do ângulo e os ajustes de curvatura são, em sua maioria, manuais. Isso torna os sistemas mecânicos inadequados para dobras com tolerâncias apertadas ou para materiais que exigem aplicação de força variável.

A segurança também representa um desafio, pois o pistão não consegue parar imediatamente após o engate do volante. Essa característica levou muitos países a eliminar gradualmente as prensas dobradeiras mecânicas em favor de modelos hidráulicos ou elétricos com sistemas eletrônicos de segurança.

Apesar da reputação antiquada, as máquinas mecânicas prosperam em ambientes que priorizam a velocidade de produção e a manutenção mínima. Pequenas oficinas de fabricação, fornecedores de estampagem e fábricas que lidam com grandes quantidades de peças uniformes frequentemente optam por modelos mecânicos devido a essas vantagens. Em regiões onde a confiabilidade do fornecimento de energia é instável, a baixa sensibilidade energética do sistema mecânico também é benéfica.

As prensas dobradeiras hidráulicas representam um ponto de virada significativo no desenvolvimento da tecnologia de dobra, principalmente porque introduziram um nível de controle e gerenciamento de força impossível de ser alcançado por máquinas mecânicas. Enquanto os sistemas mecânicos dependem do momento de inércia de componentes rotativos, as máquinas hidráulicas utilizam a pressão do fluido, permitindo que o pistão se mova com um movimento suave e regulado ao longo de todo o curso. Essa diferença transformou fundamentalmente a maneira como as fábricas abordam as tarefas de dobra. Em vez de adaptar a peça de trabalho ao comportamento fixo da máquina, os sistemas hidráulicos permitem que a máquina se adapte à peça de trabalho, o que é especialmente importante quando o comportamento do material se torna imprevisível devido a variações de espessura, flutuações de dureza ou inconsistências entre lotes.

A arquitetura de uma prensa dobradeira hidráulica é centrada em seus cilindros hidráulicos pareados, que são montados em cada lado do pistão e acionados por um circuito hidráulico de alta pressão. Quando o óleo entra nos cilindros, os pistões empurram o pistão para baixo com notável firmeza, e essa pressão pode ser modulada com precisão. Em sistemas eletro-hidráulicos modernos, válvulas proporcionais Os encoders lineares e de controle CNC trabalham em conjunto, medindo constantemente a posição do pistão e corrigindo qualquer desvio entre os lados esquerdo e direito. Isso resulta em um movimento sincronizado que permanece estável mesmo sob cargas significativas, garantindo que o pistão não incline, torça ou oscile em nenhum ponto durante a dobra. Essa confiabilidade eleva as prensas dobradeiras hidráulicas a um patamar superior ao de meras substitutas de máquinas mecânicas; elas se tornam ferramentas adaptáveis capazes de atender a uma ampla gama de requisitos industriais.

Em comparação com as tecnologias mais antigas, os sistemas hidráulicos também introduziram um novo grau de flexibilidade. Uma prensa dobradeira mecânica só consegue desenvolver sua força máxima na parte inferior do curso, enquanto um sistema hidráulico pode fornecer a tonelagem total em qualquer ponto. Essa capacidade permite que os operadores realizem dobras em V mais profundas, dobras no ar e dobras na base com maior consistência. Significa também que a máquina pode conformar materiais mais espessos, ligas de alta resistência e seções complexas sem a necessidade de ligações mecânicas especializadas ou acessórios adicionais. À medida que as indústrias começaram a produzir componentes em aço inoxidável, ligas de alumínio e aço estrutural de alta resistência, as prensas dobradeiras hidráulicas demonstraram uma capacidade superior de manter a precisão angular, apesar do aumento do retorno elástico inerente a esses materiais.

No entanto, a ampla adoção de prensas dobradeiras hidráulicas não se deve apenas à sua capacidade de força. Sua capacidade de integrar automação CNC transformou significativamente o fluxo de trabalho de dobra. Os sistemas modernos permitem que os operadores programem sequências de dobra completas, incluindo velocidade de aproximação, velocidade de dobra, tempo de permanência e comportamento de descompressão, permitindo que a máquina compense as variações em tempo real na resistência do material. Na fabricação de componentes com múltiplos ângulos, esse controle adaptativo de pressão garante que a máquina continue a fornecer resultados previsíveis, mesmo quando a peça se torna progressivamente mais rígida ou mais difícil de manusear. Para fábricas que produzem múltiplas linhas de produtos ou peças personalizadas com frequência, essa capacidade de alternar perfeitamente entre tarefas sem sacrificar a consistência é indispensável.

Apesar das suas vantagens, os sistemas hidráulicos introduziram o seu próprio conjunto de considerações. A dependência do óleo hidráulico significa que o desempenho da máquina é influenciado pela temperatura, desgaste e condição do fluido. À medida que a máquina opera durante longos turnos, o óleo aquece, alterando a sua viscosidade e as características de resposta do sistema. Os fabricantes de ponta resolveram este problema com algoritmos de compensação térmica e bombas servoacionadas, que estabilizam a pressão do sistema e reduzem o consumo desnecessário de energia. No entanto, a presença de bombas, mangueiras, válvulas e vedações também significa que as prensas dobradeiras hidráulicas requerem inerentemente mais manutenção do que os sistemas puramente mecânicos ou elétricos. A manutenção preventiva — especialmente a substituição periódica do óleo e a inspeção das vedações — continua a ser essencial para manter a máquina com a máxima precisão ao longo da sua vida útil.

Mesmo com esses desafios, as prensas dobradeiras hidráulicas se tornaram o tipo mais universalmente adotado por oferecerem uma combinação equilibrada de controle, potência e versatilidade. Pequenas oficinas dependem delas para tarefas diárias de fabricação, e grandes fabricantes de equipamentos originais (OEMs) as integram em células de dobra com múltiplas máquinas. Sua capacidade de gerar força controlada de forma consistente, adaptar-se a diversos materiais e operar sob automação CNC permite que as prensas dobradeiras hidráulicas sirvam como a "espinha dorsal industrial" para fábricas em inúmeros setores metalúrgicos. De muitas maneiras, elas representam não apenas um tipo de máquina, mas o padrão pelo qual a qualidade da dobra é avaliada na manufatura moderna.

À medida que as demandas da indústria manufatureira continuaram a se voltar para maior precisão, menor consumo de energia e ambientes de trabalho mais silenciosos, as prensas dobradeiras elétricas emergiram como uma alternativa tecnologicamente distinta aos sistemas hidráulicos. Em vez de depender de energia hidráulica, as prensas dobradeiras elétricas utilizam servomotores e sistemas de acionamento mecânico Para movimentar o pistão com excepcional precisão posicional. Essa transição da dinâmica de fluidos para o controle eletromecânico altera fundamentalmente a natureza do processo de dobra, tornando as prensas dobradeiras elétricas particularmente adequadas para aplicações em que até mesmo pequenas variações de ângulo ou consistência podem ser inaceitáveis.

No coração de uma prensa dobradeira elétrica está um conjunto de servomotores de alto desempenho, cada um conectado ao pistão através de fusos de esferas, transmissões por correia ou outros conjuntos de movimento linear. Quando a máquina inicia um ciclo, o sistema servo traduz os comandos digitais diretamente em movimento mecânico controlado. Ao contrário dos sistemas hidráulicos, que precisam regular a pressão por meio de válvulas e compensar o comportamento do óleo, os sistemas elétricos respondem puramente por meio do torque do motor e do feedback do encoder. Essa relação direta entre comando e movimento resulta em um perfil de movimento extremamente limpo, caracterizado por vibração mínima, capacidade de parada instantânea e controle preciso em nível micrométrico em cada estágio do curso.

A estabilidade do sistema elétrico permite que os fabricantes abordem a dobra como uma operação mecânica altamente repetível, em vez de um processo variável acionado por fluido. Durante longas séries de produção, os servomotores mantêm limites de movimento consistentes, garantindo que os desvios angulares sejam minimizados mesmo após milhares de ciclos. Além disso, como os sistemas elétricos não dependem de circuitos hidráulicos, eliminam vazamentos de óleo, períodos de aquecimento e variações de desempenho relacionadas à temperatura — fatores que frequentemente exigem atenção em ambientes hidráulicos. Isso torna as prensas dobradeiras elétricas particularmente atraentes para instalações onde limpeza, condições ambientais e economia de energia a longo prazo são prioridades, como fábricas de montagem eletrônica, fábricas de equipamentos médicos e de precisão. chapa metálica centros de fabricação.

No entanto, o valor das prensas dobradeiras elétricas vai além da sua precisão. A sua velocidade de resposta é notavelmente superior à dos sistemas hidráulicos em muitas operações com chapas finas. Movimentos de curso curto — comuns em peças com flanges pequenas ou geometrias complexas — beneficiam-se imensamente das capacidades de aceleração e desaceleração rápidas do servomotor. Essa eficiência aumenta significativamente na produção em larga escala, reduzindo o tempo de ciclo e aumentando a produtividade sem exigir maior consumo de energia. Como os sistemas elétricos consomem energia apenas quando o pistão está em movimento, o seu custo operacional permanece impressionantemente baixo, muitas vezes resultando em economias mensuráveis já nos primeiros meses de operação.

Apesar dessas vantagens, as prensas dobradeiras elétricas não foram projetadas para substituir as máquinas hidráulicas em aplicações de alta exigência. Os conjuntos de acionamento mecânico que lhes conferem precisão também impõem limitações na força gerada. Cargas excessivas, principalmente ao dobrar materiais muito espessos ou de alta resistência, podem causar tensão nos fusos de esferas ou nos mecanismos de correia. Os fabricantes geralmente projetam prensas dobradeiras elétricas para faixas de tonelagem leve a média, onde a precisão e a eficiência são mais importantes do que a força bruta. Fábricas que trabalham com aço estrutural pesado, chapas grossas ou componentes de grande formato continuam a preferir sistemas hidráulicos, enquanto as prensas dobradeiras elétricas dominam os setores onde o material de trabalho é mais fino e os requisitos de tolerância são mais rigorosos.

Ainda assim, a ascensão das prensas dobradeiras elétricas sinaliza uma mudança mais ampla na indústria em direção a uma manufatura inteligente e ecoeficiente. Sua capacidade de operar de forma silenciosa, limpa e previsível alinha-se perfeitamente com a crescente adoção de células de dobra automatizadas, sistemas de carregamento robotizados e integração de dados da Indústria 4.0. Nesses ambientes, o comportamento consistente das prensas dobradeiras elétricas reduz as necessidades de calibração, simplifica a programação de robôs e aumenta a confiabilidade geral dos fluxos de trabalho automatizados. Como resultado, muitos fabricantes veem as prensas dobradeiras elétricas não como uma opção de nicho, mas como um investimento estratégico na modernização a longo prazo de suas capacidades de produção.

Ao analisar os três principais tipos de prensas dobradeiras em conjunto, fica evidente que suas diferenças vão muito além da presença ou ausência de um volante, um circuito de óleo ou um servomotor. Cada tipo incorpora uma filosofia tecnológica diferente, moldada pelas prioridades de fabricação e limitações de engenharia de sua época. As prensas dobradeiras mecânicas refletem um período em que durabilidade, velocidade e simplicidade determinavam o valor dos equipamentos de fabricação. As prensas dobradeiras hidráulicas representam a mudança industrial em direção a um comportamento controlado, distribuição flexível de força e operação mais segura. As prensas dobradeiras elétricas, por outro lado, alinham-se com a ênfase moderna em precisão, consistência baseada em dados e responsabilidade energética. Compreender como essas filosofias influenciam o desempenho no mundo real é muito mais importante do que memorizar qualquer lista estática de vantagens.

Em operação, as máquinas mecânicas dependem da previsibilidade do seu sistema de articulação. Sua curva de potência segue o movimento natural do virabrequim, fornecendo força máxima apenas no ponto morto inferior. Isso as torna adequadas para tarefas de dobra repetitivas com geometrias estáveis, mas muito menos adaptáveis quando os materiais apresentam retorno elástico imprevisível ou quando o operador precisa executar dobras parciais com controle preciso do ângulo. As máquinas hidráulicas resolveram essa inflexibilidade introduzindo o controle de fluido pressurizado que mantém a força ao longo de todo o curso. Com a pressão modulada por válvulas e monitorada pelo feedback do CNC, os sistemas hidráulicos permitem que o comportamento da dobra seja adaptado ao material, em vez de forçar o material a se conformar ao movimento da máquina. Como resultado, os operadores podem obter ângulos consistentes com uma variedade maior de materiais, mesmo aqueles que as máquinas mecânicas têm dificuldade em manusear de forma confiável.

As prensas dobradeiras elétricas levam esse conceito ainda mais longe, transformando a dobra de um processo regulado por pressão em um processo controlado por posição. Em vez de gerenciar a dinâmica de fluidos ou depender do momento mecânico, os sistemas elétricos usam servomotores para gerar movimentos diretamente vinculados a comandos digitais. Isso possibilita uma trajetória do pistão excepcionalmente previsível, uma característica valiosa não apenas para tolerâncias rigorosas, mas também para dobra robótica Em ambientes onde até mesmo pequenas variações de posição podem interromper todo um fluxo de trabalho automatizado, os sistemas hidráulicos adaptam sua força ao material, enquanto os sistemas elétricos garantem que o movimento em si seja inerentemente estável, o que os torna particularmente eficazes na fabricação de chapas finas e de precisão.

Outra diferença surge ao considerarmos o comportamento de cada máquina ao longo de ciclos de produção prolongados. As máquinas mecânicas mantêm sua vantagem de velocidade de forma consistente, mas sua precisão depende muito das condições de desgaste dos componentes mecânicos. Os sistemas hidráulicos, embora mais adaptáveis, são sensíveis à temperatura do óleo e à condição das vedações a longo prazo. As prensas dobradeiras elétricas eliminam completamente essas preocupações, mantendo o mesmo perfil de movimento do primeiro ao último ciclo, desde que o sistema servo permaneça dentro de sua faixa de carga projetada. Essa independência ambiental é um dos motivos pelos quais as fábricas focadas em componentes críticos para a qualidade integram cada vez mais prensas dobradeiras elétricas em suas operações.

A conversa estaria incompleta sem reconhecer como cada tipo de máquina influencia o fluxo de trabalho do operador. As máquinas mecânicas exigem um operador mais experiente, que compreenda as nuances de tempo, profundidade do curso e reação do material; elas recompensam a habilidade, mas oferecem assistência limitada a usuários inexperientes. Os sistemas hidráulicos, com controles CNC e sequências de pressão programáveis, permitem uma participação mais ampla do operador, reduzindo a curva de aprendizado para novos funcionários, ao mesmo tempo que recompensam os operadores experientes com oportunidades de ajustes finos de precisão. As prensas dobradeiras elétricas vão além, tornando muitos ajustes tradicionais desnecessários; a estabilidade de movimento da máquina minimiza as tentativas e erros normalmente associadas à obtenção do ângulo correto, tornando-as ideais para fábricas que priorizam a repetibilidade ou operam com equipes reduzidas.

Por fim, quando analisada sob uma perspectiva econômica, a relação custo-benefício de cada tipo de prensa dobradeira torna-se mais clara. As prensas dobradeiras mecânicas têm baixo custo de manutenção, mas carecem da adaptabilidade necessária para os modernos ambientes de produção mista. As máquinas hidráulicas oferecem uma estrutura de custos equilibrada, capazes de lidar com tarefas leves e pesadas, mantendo a manutenção gerenciável. As prensas dobradeiras elétricas exigem um investimento inicial maior, mas compensam com custos operacionais mais baixos e maior precisão, criando valor a longo prazo para fábricas que priorizam tolerâncias rigorosas e eficiência energética. Vistos dessa forma, os três tipos não são concorrentes, mas sim ferramentas especializadas otimizadas para diferentes realidades industriais.

Escolher o tipo certo de prensa dobradeira não é uma questão simples de comparar características ou capacidades de produção; começa com a compreensão da natureza dos produtos a serem fabricados e do tipo de ambiente de produção em que a máquina irá operar. A decisão depende da frequência com que os materiais são trocados, da rigidez das tolerâncias exigidas, do tamanho ou peso das peças e se a produção prioriza volume, flexibilidade ou precisão. Quando essas considerações são analisadas cuidadosamente, a lógica por trás da escolha de um tipo em detrimento de outro torna-se significativamente mais clara.

Fábricas que produzem grandes volumes de peças com formas simples geralmente preferem prensas dobradeiras mecânicas devido à sua velocidade de ciclo e operação descomplicada. Nesses ambientes, a previsibilidade é mais importante do que a adaptabilidade, e os operadores normalmente trabalham com as mesmas ferramentas e os mesmos materiais dia após dia. O movimento consistente, impulsionado por articulações, do sistema mecânico suporta esse tipo de trabalho, garantindo que a produtividade permaneça alta sem exigir ajustes constantes. No entanto, assim que a variedade de produtos aumenta ou a precisão angular se torna mais crítica, as limitações dos sistemas mecânicos começam a aparecer.

As prensas dobradeiras hidráulicas são a escolha ideal para fábricas com cargas de trabalho variáveis. Se a linha de produção lida com diferentes materiais ao longo da semana — aço inoxidável fino em um dia, aço carbono mais espesso no dia seguinte — a capacidade de um sistema hidráulico modular a pressão dinamicamente se mostra inestimável. Essa adaptabilidade permite que as fábricas aceitem uma gama maior de pedidos, sabendo que a máquina manterá um comportamento de dobra estável, independentemente das inconsistências do material. Além disso, os sistemas hidráulicos se integram perfeitamente à automação CNC, tornando-os adequados para peças com múltiplas dobras que exigem sequenciamento preciso e movimento coordenado entre o cabeçote e o batente traseiro.

Quando as tolerâncias se tornam ainda mais restritas, ou quando as peças exigem extrema consistência entre lotes, as vantagens se voltam para as prensas dobradeiras elétricas. Seu movimento controlado digitalmente elimina as variáveis decorrentes do comportamento do fluido hidráulico, tornando-as ideais para produtos que precisam manter ângulos idênticos em milhares de peças. Indústrias como a eletrônica, a aeroespacial e a de equipamentos médicos frequentemente atuam nesse cenário de alta precisão, e as prensas dobradeiras elétricas oferecem um caminho estável para atender a essas expectativas. Seu rápido tempo de resposta também beneficia fábricas que operam com cursos curtos ou que trabalham com grandes quantidades de componentes pequenos, onde pequenas reduções no tempo de ciclo se traduzem em ganhos significativos de eficiência.

Outro fator frequentemente negligenciado na seleção de máquinas é a natureza da própria instalação. Fábricas que buscam reduzir o ruído ou implementar políticas ambientalmente responsáveis tendem a adotar prensas dobradeiras elétricas, pois operam silenciosamente e consomem energia apenas durante o movimento ativo. Por outro lado, instalações com infraestrutura hidráulica existente — equipe de manutenção, peças de reposição ou sistemas de gerenciamento de óleo compatíveis — geralmente consideram as máquinas hidráulicas mais eficientes para integrar. Até mesmo a temperatura ambiente da fábrica pode influenciar a escolha, já que ambientes extremos podem comprometer a estabilidade dos sistemas hidráulicos, a menos que tecnologias de compensação adicionais sejam instaladas.

Uma dimensão final envolve a estratégia operacional de longo prazo. Se uma empresa pretende automatizar sua linha de dobra com manipuladores robóticos, as prensas dobradeiras elétricas oferecem repetibilidade incomparável, enquanto as prensas dobradeiras hidráulicas podem exigir mais calibração ao longo do tempo. Se a fábrica se especializa em componentes estruturais pesados, nenhum modelo elétrico substituirá a capacidade de uma máquina hidráulica de grande porte. E para oficinas menores que realizam dobras de rotina sem exigir a tecnologia mais recente, uma prensa dobradeira hidráulica ou mecânica bem conservada pode oferecer mais valor do que uma alternativa elétrica de ponta.

Portanto, selecionar a máquina certa não se trata tanto de escolher a “melhor” prensa dobradeira, mas sim aquela cujo comportamento se alinha mais estreitamente com a identidade de produção atual e futura da fábrica. Quando esse alinhamento é alcançado, a prensa dobradeira se torna mais do que uma ferramenta de dobra — ela se transforma em um ativo estratégico que fortalece a posição competitiva da fábrica.

À medida que o cenário global da indústria manufatureira continua a evoluir, a tecnologia de prensas dobradeiras está silenciosamente passando por sua própria transformação — impulsionada não apenas pela busca por maior precisão de dobra, mas também pelas mudanças nas expectativas em relação ao consumo de energia, integração digital, distribuição de habilidades da força de trabalho e automação de fábrica. Esses fatores, em conjunto, redefinem o que a próxima geração de prensas dobradeiras deve oferecer. Sejam mecânicas, hidráulicas ou elétricas, cada tipo de máquina está sendo influenciado pela tendência mais ampla em direção a uma produção inteligente, adaptativa e ambientalmente responsável.

No passado, a inovação na indústria de prensas dobradeiras focava principalmente em melhorias estruturais — estruturas mais robustas, chapas laterais mais espessas e usinagem mais precisa. Embora esses elementos continuem importantes, a vantagem competitiva moderna reside agora nos algoritmos de controle e na arquitetura de dados. Para prensas dobradeiras hidráulicas, a integração de sistemas de bombas servoacionadas representa um grande avanço. Em vez de manter a bomba hidráulica funcionando continuamente, esses novos sistemas são acionados somente quando a máquina requer movimento, reduzindo significativamente o consumo de energia, o ruído e a geração de calor. Mais importante ainda, as bombas servo introduzem um nível refinado de resposta à pressão, aprimorando a consistência da dobra e prolongando a vida útil do sistema hidráulico. Essa evolução híbrida permite que as prensas dobradeiras hidráulicas permaneçam relevantes em um mundo cada vez mais preocupado com padrões ambientais e custos operacionais.

Em paralelo, as prensas dobradeiras elétricas estão se tornando rapidamente a referência para a manufatura de precisão. Seu desenvolvimento contínuo gira em torno da melhoria da capacidade de força, da redução do estresse mecânico nos componentes de acionamento e da expansão da aplicabilidade para além do trabalho com chapas finas. Os fabricantes estão experimentando conjuntos de fusos de esferas reforçados e servomotores mais potentes, impulsionando gradualmente as prensas dobradeiras elétricas para o segmento de média tonelagem. Embora esse crescimento não diminua a necessidade de sistemas hidráulicos em dobras pesadas, ele sinaliza um futuro onde as prensas dobradeiras elétricas desempenharão um papel muito mais amplo na fabricação em geral, em vez de ocupar um nicho restrito. Além disso, sua compatibilidade com sistemas de manutenção preditiva — baseados na análise de curvas de carga do servomotor, assinaturas de vibração e contagens de ciclos — as posiciona como altamente adequadas para fábricas inteligentes, onde o planejamento de tempo de atividade é orientado por dados, em vez de reativo.

Os ecossistemas digitais também desempenham um papel cada vez mais importante. Os modernos sistemas CNC não são apenas interfaces de programação; são portais que conectam a prensa dobradeira a plataformas de dados corporativas. A integração com a Indústria 4.0 permite o monitoramento e a análise em tempo real do desempenho da máquina, da eficiência do operador, do uso de ferramentas e dos intervalos de manutenção. Essa infraestrutura interconectada permite que as fábricas detectem desvios precocemente, otimizem a alocação de máquinas com base na carga de trabalho e na complexidade, e gerem cronogramas de produção mais previsíveis. Para sistemas elétricos, essa sinergia digital é ainda mais impactante, pois seus padrões de movimento consistentes produzem fluxos de dados mais limpos, permitindo que os algoritmos detectem irregularidades com maior precisão. Os sistemas hidráulicos, com sua dinâmica mais variável, ainda se beneficiam muito do monitoramento inteligente, principalmente na identificação de sinais precoces de desgaste de válvulas ou degradação do óleo antes que afetem a precisão da dobra.

A automação é outra fronteira fundamental. O surgimento de robôs colaborativos e células de dobra automatizadas força os fabricantes a reconsiderarem as qualidades que uma prensa dobradeira deve possuir. Em fluxos de trabalho automatizados, a máquina não pode depender da intuição do operador ou da correção manual de ângulos; a prensa dobradeira deve apresentar um comportamento altamente repetível, ciclo após ciclo, sem falhas. As prensas dobradeiras elétricas dominam atualmente esse segmento, pois seu movimento servoacionado reduz a necessidade de compensação de ângulos e minimiza desvios imprevisíveis. No entanto, modelos hidráulicos de alta gama, com controle avançado de válvulas e algoritmos de sincronização em tempo real, também estão se mostrando cada vez mais compatíveis com sistemas automatizados. À medida que a dobra robótica se torna mais comum — mesmo em oficinas menores — a distinção entre prensas dobradeiras adequadas para operação manual e prensas adequadas para automação se tornará mais evidente, influenciando a forma como os fabricantes projetam seus produtos futuros.

Finalmente, as considerações de sustentabilidade estão começando a influenciar a seleção de equipamentos de maneiras nunca antes vistas. Governos e empresas estão priorizando a redução da pegada de carbono nas operações de manufatura. As prensas dobradeiras elétricas se alinham naturalmente a esses objetivos devido ao seu baixo consumo de energia e à ausência de óleo hidráulico. Enquanto isso, os fabricantes de prensas dobradeiras hidráulicas estão introduzindo óleos mais limpos, tecnologias de prevenção de vazamentos e sistemas de bombas com eficiência energética para atender a expectativas semelhantes. A longo prazo, essas pressões ambientais provavelmente acelerarão a inovação em todos os tipos de prensas dobradeiras, impulsionando as filosofias de projeto em direção a soluções mais silenciosas, limpas e com maior eficiência no uso de recursos.

Em conjunto, essas tendências sugerem que o futuro da tecnologia de prensas dobradeiras não será definido pelo domínio de um único tipo de máquina. Em vez disso, refletirá um espectro de opções moldado pela inteligência digital, prontidão para automação, eficiência energética e adaptabilidade de materiais. As prensas dobradeiras mecânicas, embora não sejam mais centrais para a inovação moderna, continuarão a desempenhar funções específicas onde a simplicidade e a velocidade superam as necessidades de controle avançado. Os sistemas hidráulicos permanecerão a espinha dorsal da fabricação robusta e versátil. As prensas dobradeiras elétricas assumirão cada vez mais o protagonismo em ambientes de produção automatizados e de alta precisão. Nesse cenário em evolução, cada tecnologia encontra seu lugar dentro de um ecossistema de manufatura mais complexo e interconectado.

Compreender as diferenças entre prensas dobradeiras mecânicas, hidráulicas e elétricas significa, em última análise, entender como cada máquina interpreta o ato de dobrar. As máquinas mecânicas o abordam como uma questão de tempo e impulso. Os sistemas hidráulicos o tratam como pressão controlada aplicada com precisão. As máquinas elétricas o percebem como um movimento preciso definido por uma intenção digital. Essas perspectivas não são mutuamente exclusivas; elas representam soluções diferentes para o desafio universal de moldar metal com precisão, repetibilidade e eficiência.

As prensas dobradeiras mecânicas nos lembram que velocidade e durabilidade ainda são valiosas em certos ambientes de fabricação, especialmente onde a geometria do produto permanece estável e o tempo de ciclo determina a lucratividade. As prensas dobradeiras hidráulicas demonstram por que a versatilidade e a modulação de força se tornaram indispensáveis, permitindo que as fábricas aceitem trabalhos complexos com confiança. As prensas dobradeiras elétricas revelam o caminho a seguir — um caminho onde a consistência digital, a consideração ambiental e a compatibilidade com a automação redefinem o que os operadores esperam de uma máquina de dobra.

Portanto, selecionar a prensa dobradeira ideal não se resume a escolher a tecnologia mais recente ou mais potente. Trata-se de alinhar o comportamento da máquina à identidade da fábrica. Uma fábrica que prospera com projetos personalizados precisa da adaptabilidade dos sistemas hidráulicos; uma que produz componentes complexos e de alta precisão se beneficia mais do controle elétrico de movimento; uma que valoriza a velocidade em trabalhos repetitivos pode continuar confiando na tecnologia mecânica. Quando esse alinhamento é alcançado, a prensa dobradeira se torna uma extensão da estratégia da fábrica, e não apenas um equipamento.

À medida que a indústria manufatureira incorpora inteligência, eficiência energética e automação, as distinções entre os tipos de prensas dobradeiras deixarão de ser vistas como categorias rígidas. Em vez disso, serão compreendidas como diferentes expressões da engenharia, adaptadas a diferentes realidades industriais. Nesse sentido, cada prensa dobradeira — mecânica, hidráulica ou elétrica — conta a história de sua época, ao mesmo tempo que se adapta às demandas da próxima. E para os fabricantes, engenheiros e operadores que dependem dessas máquinas diariamente, compreender essas diferenças é o primeiro passo para construir um fluxo de trabalho de dobra que seja não apenas eficiente, mas também preparado para o futuro.

Uma prensa dobradeira é uma máquina usada para dobrar chapas metálicas em formatos específicos. Ela pressiona uma chapa de metal entre um punção e uma matriz, criando dobras e vincos. Essas máquinas vêm em diferentes tipos — mecânicas, hidráulicas e elétricas — cada uma adequada para diversas tarefas de dobra.

Os três principais tipos de prensas dobradeiras são as mecânicas, hidráulicas e elétricas. As prensas dobradeiras mecânicas utilizam um sistema de volante para velocidade, as hidráulicas usam fluido hidráulico para precisão e as elétricas utilizam servomotores para garantir movimentos precisos. Cada tipo possui vantagens específicas para diferentes necessidades de dobra de metais.

A escolha da prensa dobradeira ideal depende das suas necessidades de produção. Para tarefas repetitivas e de alta velocidade, os modelos mecânicos são os mais indicados. Para materiais diversos ou dobras complexas que exigem flexibilidade, as prensas dobradeiras hidráulicas são a melhor opção. Se precisão e baixo consumo de energia são suas prioridades, as prensas dobradeiras elétricas podem ser a escolha certa.

As prensas dobradeiras podem dobrar diversos materiais, incluindo aço inoxidável, alumínio e aço de alta resistência. O tipo de prensa dobradeira influencia a sua capacidade de lidar com materiais específicos, especialmente se forem espessos ou exigirem tolerâncias rigorosas.

Sim! As prensas dobradeiras mecânicas ainda são úteis, especialmente em ambientes onde a velocidade é crucial. Elas são confiáveis para tarefas repetitivas que não exigem dobras complexas, o que as torna populares para trabalhos simples e de grande volume.

As prensas dobradeiras elétricas estão ganhando popularidade devido à sua precisão e eficiência energética. Elas operam silenciosamente, produzem menos desperdício e oferecem dobras de alta precisão, o que é fundamental para indústrias como a eletrônica e a de equipamentos médicos.

As prensas dobradeiras mecânicas são geralmente as mais rápidas, ideais para grandes volumes de produção, enquanto as prensas dobradeiras hidráulicas oferecem maior adaptabilidade para diversas tarefas, e as prensas dobradeiras elétricas proporcionam precisão que pode levar a aumentos gerais de produtividade, apesar das velocidades mais lentas.

A manutenção de prensas dobradeiras envolve verificações regulares dos níveis de fluido hidráulico e das vedações, no caso dos modelos hidráulicos, enquanto os sistemas mecânicos exigem o monitoramento do desgaste das peças móveis. As prensas dobradeiras elétricas necessitam de manutenção menos frequente, mas a verificação dos servomotores e das conexões continua sendo importante.

Sim! Muitas prensas dobradeiras modernas, especialmente as elétricas e hidráulicas, podem ser integradas a sistemas CNC e robôs para operações de dobra automáticas. Isso reduz o trabalho manual e aumenta a eficiência, principalmente em fábricas com alta demanda de produção.

Fonte de referência: