Assine nossa newsletter

Insira seu endereço de e-mail abaixo e inscreva-se em nossa newsletter.

Insira seu endereço de e-mail abaixo e inscreva-se em nossa newsletter.

Among all sheet-metal fabrication machines, the press brake holds a unique position. It is one of the oldest, most versatile, and most essential tools in any fabrication environment—from small family-run workshops to multinational OEM factories. Whether working with simple brackets or precision aerospace components, manufacturers rely on the press brake to transform flat sheet metal into parts with accurate bends, angles, and geometric profiles. For beginners stepping into the metal fabrication field, understanding how a press brake works is foundational, because it affects how designs are engineered, how production workflows are planned, and how bending quality and cost can be controlled.

Although modern press brakes incorporate increasingly advanced CNC systems, servo-electric drives, offline programming, and intelligent crowning systems, the underlying bending principle has remained remarkably consistent for decades. This creates an interesting blend of tradition and innovation: craftsmen with decades of experience still rely on tactile knowledge and bending intuition, while new operators depend on 3D graphical interfaces and automatic tooling suggestions. To understand both worlds, it is important to start from the fundamentals—what a press brake is, what functions it performs, and why it is so crucial to sheet-metal bending.

This guide is written for absolute beginners who may never have touched a press brake before, as well as new engineers, buyers, and business owners entering the sheet-metal industry. The explanations intentionally avoid overly academic formulas and instead emphasize conceptual clarity, industry terminology, real-world usage, and practical value. Once you complete this guide, you will not only understand what a press brake is, but also how to differentiate between machine types, how bending principles work, how tooling affects accuracy, and how modern CNC systems simplify programming and improve repeatability.

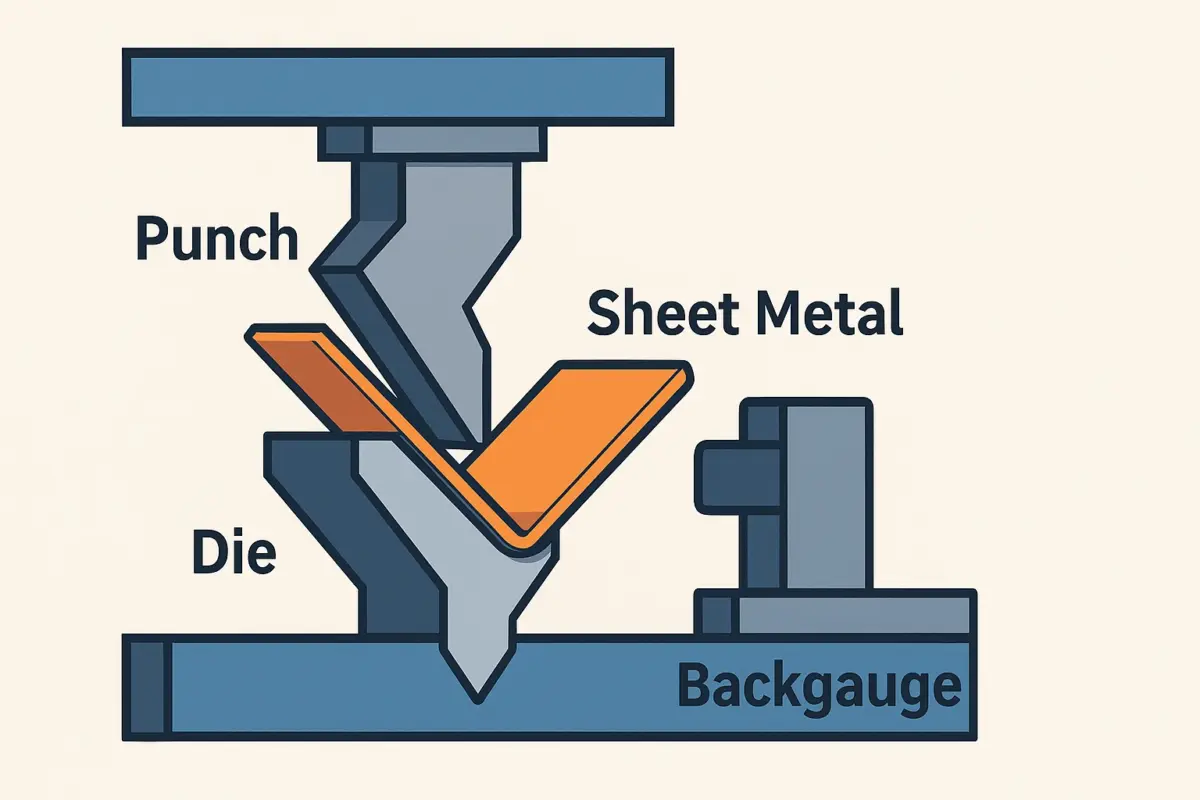

A press brake is a machine used to bend sheet metal by pressing it between a punch and a die. At its core, the machine creates deformation through applied force, and that force can come from hydraulic systems, electric servo motors, mechanical flywheels, or pneumatic cylinders. No matter what drive system is used, the purpose remains consistent: to create precise angles and shapes in metal sheets by controlling the motion of the upper beam, lower table, or both.

A modern press brake is much more than a simple bending device. It is a combination of mechanical rigidity, intelligent control, safety systems, precision tooling, and operator skill. The quality of a bend does not depend only on the force applied; it also depends on factors such as the material thickness, grain direction, die width, punch shape, backgauge accuracy, crowning compensation, and even the operator’s understanding of how metals behave during plastic deformation. Because of this complexity, many new users assume a press brake is simply a force machine, but experienced machinists know it is actually a precision instrument requiring careful adjustment and knowledge.

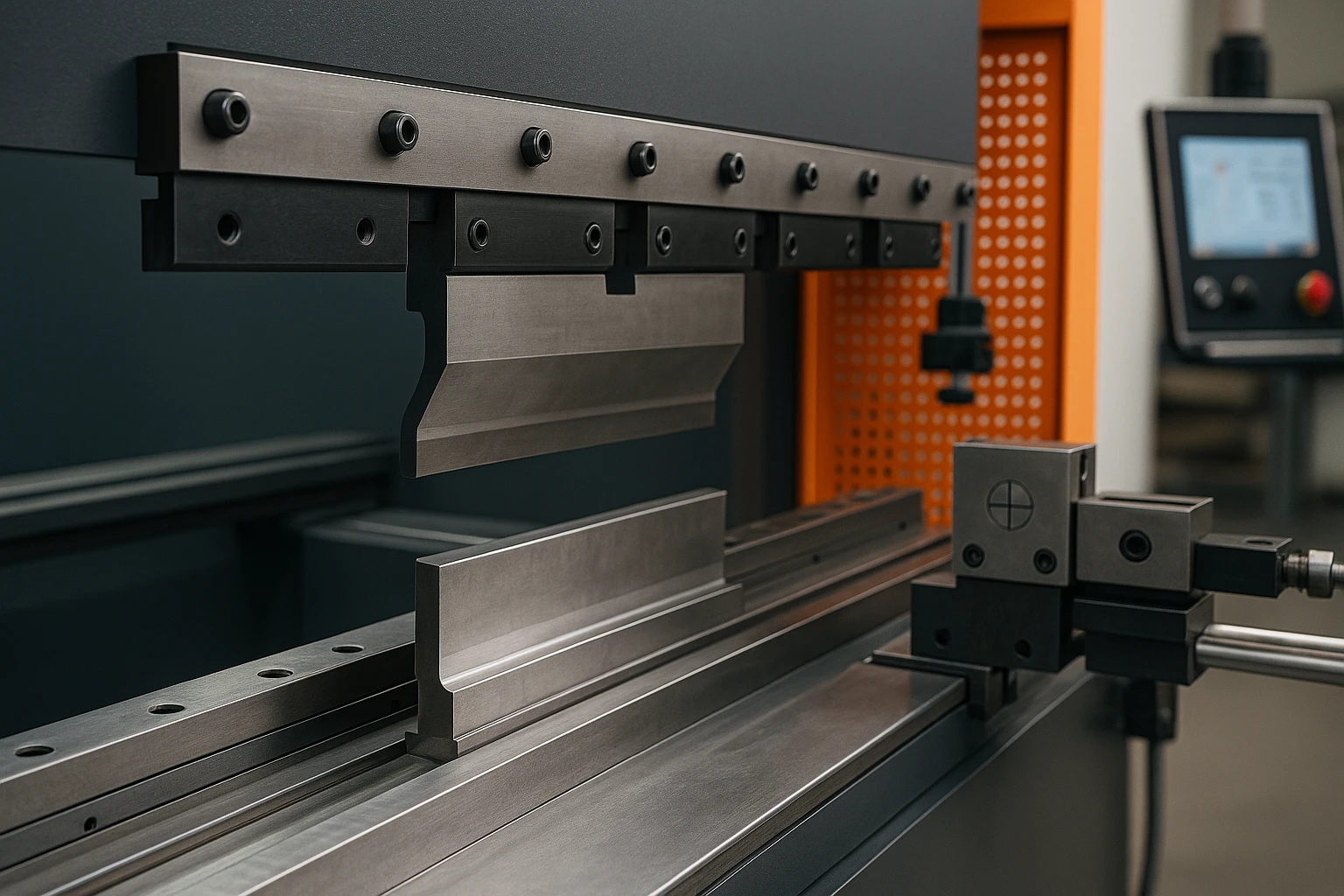

When engineers talk about “a press brake,” they typically refer to a standard hydraulic or CNC hydraulic model found in modern fabricating factories. These machines usually have a synchronized dual-cylinder system, a robust welded frame, and a backgauge that positions the sheet metal before bending. More advanced versions include multi-axis backgauges, automatic tool changers, angle-measuring systems, and large 3D touch-screen controllers that guide operators through each step of the bending process. At the same time, simpler mechanical or manual press brakes still exist and are widely used for lighter fabrication tasks or educational purposes.

Understanding the definition of a press brake also requires distinguishing it from other bending machines. Roll benders create curved profiles by progressively rolling sheet metal. Folding machines bend material by lifting a clamping beam. Stamping presses perform high-speed, high-volume forming. In contrast, a press brake is designed specifically for controlled, accurate, linear bending along a straight axis. This makes it ideal for manufacturing parts such as cabinets, enclosures, frames, brackets, doors, channels, and countless other sheet-metal components.

Although the primary purpose of a press brake is bending, the machine actually performs several distinct functions depending on the tooling installed and the skills of the operator. Understanding these functions helps beginners recognize the flexibility and importance of the machine.

This is the most basic and fundamental operation. The punch descends into the die, forcing the metal to bend at a specific angle. Manufacturers use V-dies of different widths to accommodate materials of different thicknesses. Linear bending is used to create U-shaped channels, L-angle brackets, box components, and a wide range of enclosures.

Air bending uses a die opening larger than the material thickness, allowing the punch to control the bend angle by adjusting penetration depth. This method requires less force than bottoming and gives the operator more flexibility. Most modern press brake applications rely on air bending because it is efficient and allows for angle adjustments without changing the die.

In bottom bending, the punch forces the material to conform tightly to the die. This method creates more consistent angles but requires higher tonnage and dedicated tooling. It is used when high-precision bends or unique shapes are needed, although it results in lower tooling flexibility compared to air bending.

Coining is a high-pressure bending method in which the punch deeply penetrates the material inside the die, permanently imprinting the punch shape. This creates extremely accurate bends with minimal springback. Coining is used for specialized parts requiring ultra-high precision but is less common today due to the rise of advanced CNC systems and high-quality air bending.

By performing a series of bends, a press brake can fold sheet metal onto itself to create a hem (a flattened fold). Hems are often used to improve strength, eliminate sharp edges, or prepare a part for fastening. Hemming requires special tools or a combination of air bends and flattening tools.

An offset bend creates a Z-shape geometry in the metal. It requires a special “gooseneck” or offset punch and matching die. Offset bends are often used in brackets or overlapping joints.

Despite these different bending techniques, the press brake remains a single machine type capable of performing all these functions by simply changing tooling and adjusting settings.

A beginner might wonder why the press brake is so common in factories worldwide. The reason is its combination of versatility, efficiency, precision, and cost-effectiveness. Few machines in a fabrication shop handle as many different tasks as the press brake, and even fewer allow operators to switch designs quickly without major setup changes.

Press brakes are essential because they can bend a wide variety of materials, including steel, stainless steel, aluminum, brass, copper, and even some composite or coated sheets. They are used to create everything from small appliance components to large structural frames. The ability to make complex shapes by bending instead of welding also reduces part weight, increases strength, and lowers production costs. This is particularly important in industries such as HVAC, electrical enclosures, automotive components, elevators, air-conditioning units, construction panels, and agricultural machinery.

Another reason the press brake is vital is its ability to respond to low-volume and high-mix production. In modern manufacturing, customers demand customized products in small batches. Unlike stamping dies—which require expensive molds—press brakes can produce a prototype or small order quickly and inexpensively. A skilled operator can create new bends by simply adjusting the backgauge, selecting the right tooling, and entering the required angle. This makes press brakes essential for prototyping, small-series production, and flexible manufacturing cells (FMCs).

The rise of CNC press brakes has further expanded their importance. Advanced controllers allow operators to visualize bends in 3D, detect potential collisions before bending, and automatically calculate bend sequences and backgauge positions. These features significantly reduce operator skill requirements, making it easier for factories to train new workers and maintain consistent quality. This is particularly valuable in countries facing skilled-labor shortages.

To understand a press brake thoroughly, beginners must first grasp the fundamental bending principle. Although a modern machine may appear complex—with CNC axes, servo motors, proportional valves, and advanced sensors—the bending mechanism itself is grounded in simple mechanical interaction. A sheet of metal is placed across a die, and a punch presses down to deform the sheet along a straight line. The metal is forced to yield, and that plastic deformation becomes a permanent bend.

When the punch begins pressing, the metal initially undergoes elastic deformation—a temporary change in shape that will return to flat once the pressure is removed. Only after the applied force exceeds the material’s yield strength does the sheet enter plastic deformation, where the shape change becomes permanent. This is the phase in which bending actually occurs.

Understanding this distinction is important because of a phenomenon known as retorno elástico. After a bend is made and the punch retracts, the material will try to return slightly toward its original position due to elastic recovery. This affects bend angle accuracy. Modern CNC press brakes automatically compensate for springback through angle sensors, CNC algorithms, or by adjusting the penetration depth of the punch.

Air bending is the most common bending method used today because it requires less tonnage and provides angle flexibility. In this process, the punch does not reach the bottom of the die. Instead, the sheet touches the punch tip and the two top edges of the V-die, forming a three-point contact.

The angle is determined by:

Because multiple angles can be produced with the same die, air bending simplifies tooling inventory and increases production speed.

In bottom bending, the punch pushes the metal until it fully conforms to the die angle. This method reduces springback but requires more precise tooling and higher force. It is used for:

Although less flexible than air bending, bottoming is still favored in applications requiring stable geometric control.

Coining is a much older bending method. The punch penetrates deeply into the sheet, imprinting the punch profile into the material. Because of the extreme pressure involved, springback is almost eliminated. Although useful for precision components, coining has largely declined due to high tooling wear, large tonnage requirements, and the rise of CNC compensation technologies.

Modern press brakes use CNC controllers to automate nearly every aspect of bending:

The controller analyzes the material thickness, angle, and tooling shape to determine the correct penetration depth. Some systems go even further by offering:

This digital intelligence reduces operator dependency and significantly improves productivity and quality.

A press brake’s performance depends heavily on the quality and engineering of its mechanical components. Understanding each part helps beginners interpret datasheets, compare different brands, and evaluate machine quality.

The frame is the backbone of the machine. A typical press brake has a C-frame or monoblock welded steel structure designed to withstand enormous force without deflecting. Rigidity is essential because even microscopic changes in frame deformation can affect bend accuracy. High-quality press brakes undergo stress-relief processes, such as:

A rigid frame improves stability, ensures consistent accuracy, and prolongs machine lifespan.

Most modern press brakes are hydraulic ou servoelétrico.

prensas dobradeiras hidráulicas use two synchronized cylinders to control the upper beam. They offer high force, smooth motion, and stable performance. High-end models use proportional valves and closed-loop systems for precise movement control.

Servo-electric press brakes replace hydraulic oil with electric servo motors and belt mechanisms. They offer:

However, they are generally lower in tonnage and best suited for thin-sheet applications such as metal cabinets, elevators, lighting fixtures, or aluminum panels.

The upper beam holds the punch, while the lower table holds the die. Their alignment is crucial. Modern machines use:

These systems ensure smooth operation and minimize wear.

The backgauge positions the sheet metal before bending. It determines the bend width and ensures repeatability. Entry-level press brakes use X-axis movement (forward and backward), while advanced models may include:

The backgauge allows precise positioning for complex multi-step bends.

Tooling greatly affects bending quality, flexibility, and force requirements. A standard press brake uses:

High-end machines use mechanical or hydraulic clamping systems for quick tool changes.

When bending long pieces, the frame and table naturally deflect due to pressure. Crowning systems compensate for this deflection so that angles remain consistent across the entire workpiece. There are two types:

Hydraulic crowning automatically adjusts pressure along the table to eliminate bending inaccuracies.

The controller is the “brain” of the press brake, managing all axes and bending logic. Popular brands include:

The CNC system supports:

A modern CNC press brake is often judged by the sophistication of its controller.

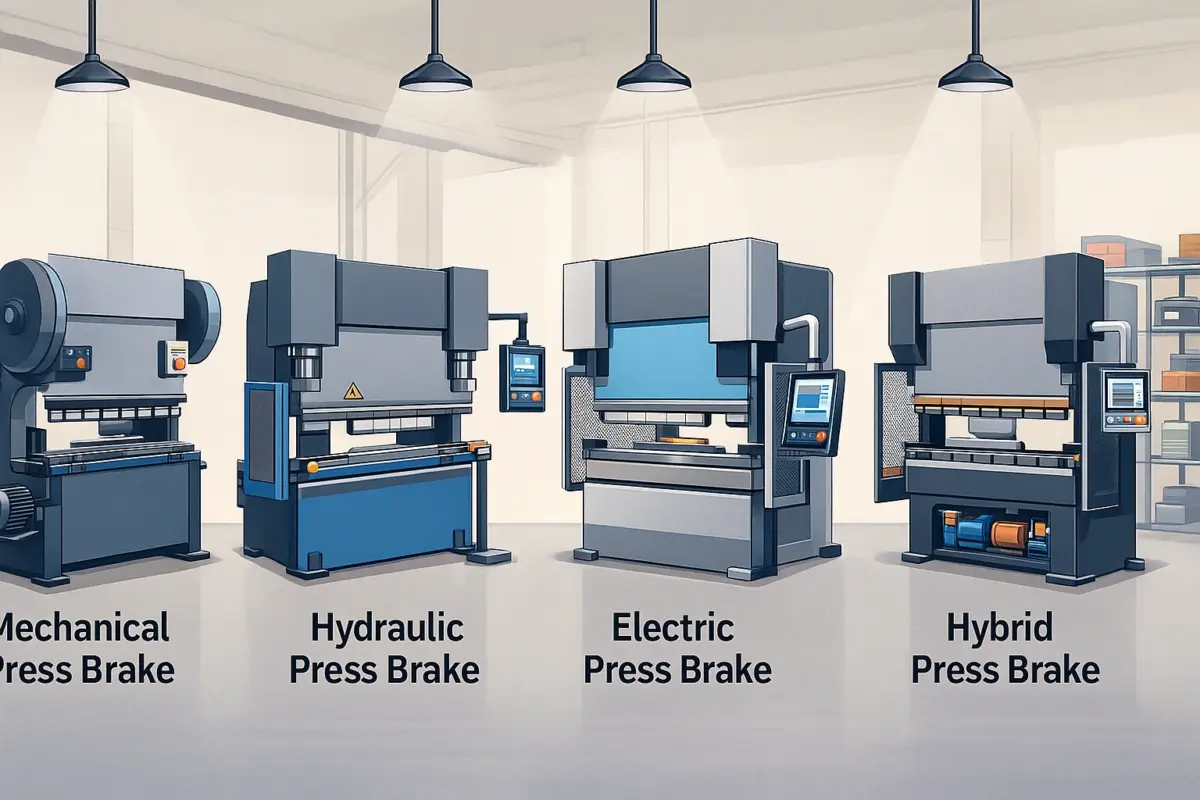

Press brakes come in several types depending on their drive system, configuration, and intended application.

Mechanical press brakes use a flywheel powered by a motor. When the operator engages the clutch, the flywheel releases energy to move the ram downward.

Vantagens:

Limitations:

Although widely used in the 1970s–1990s, mechanical press brakes are now considered outdated and less safe.

Hydraulic press brakes have become the industry standard for the past three decades. They use hydraulic cylinders to control the ram movement.

Vantagens:

Limitations:

Hydraulic press brakes dominate heavy-duty industries such as construction, shipbuilding, and machinery manufacturing.

These machines combine hydraulic power with advanced CNC control.

Key features:

They deliver:

Today, CNC hydraulic press brakes are the most widely used models globally.

Servo-electric systems use a ball-screw or belt drive powered by servo motors.

Vantagens:

Limitations:

These machines are increasingly popular for electronics, lighting, and aluminum industries.

When very long workpieces must be bent—up to 6–12 meters—factories use two press brakes synchronized together.

Applications:

Tandem systems require an advanced controller to maintain synchronization, but they provide unmatched flexibility for large-scale projects.

Press brake tooling is one of the most critical contributors to bending quality. Even the best CNC system cannot compensate for poorly selected or worn-out tools. Tooling determines the radius of the bend, the tonnage required, the achievable angle, and the likelihood of defects such as cracking or galling. Beginners often underestimate the importance of tooling, viewing it as an accessory rather than a precision component. In reality, tooling represents a technical foundation for consistent sheet-metal bending.

A punch is the upper tool that physically forces the material into the die. Punch styles vary depending on bending geometry, clearance needs, and radius requirements.

Straight Punch

The simplest punch, used for general-purpose bends where no interference occurs between the punch and the workpiece. It is suitable for standard 90°, 120°, and 30° bends.

Gooseneck Punch

Gooseneck punches have a cut-out or recessed design that provides clearance for previously bent flanges. Without such clearance, the punch might collide with a bent section. This punch is essential for producing box shapes, channels, and parts with return bends.

Acute-Angle Punch

Designed for bending acute angles (less than 90°). These punches have sharper tips, often used in combination with acute-angle dies to produce V-shaped profiles or sharp corners.

Radius Punch

Used when components require a specific radius rather than a sharp angle. Applications include architectural panels, aluminum trims, and automotive interior components.

Hemming Punch

Hemming punches work in two stages: first, creating a partial bend, and second, flattening the sheet into a smooth hem. These tools are typically used for safety edges, automotive panels, and thin-gauge steel products.

Offset Punch

Used with an offset die to create Z-shaped or joggled bends. These are often seen in brackets and sheet-metal overlapping joints.

Each punch is carefully engineered for strength, durability, and precision. High-quality punches are hardened and ground to exact tolerances, ensuring long service life and stable performance.

The die is the lower tool that receives the sheet metal during bending. Its design affects the angle, radius, and required tonnage.

Standard V-Dies

The most common die type. These come in various opening widths (e.g., 8 mm, 12 mm, 16 mm, 32 mm). A general rule is the “8T rule,” where the die opening is approximately 8 times the sheet thickness for air bending.

Acute-Angle Dies

Used for sharp or acute bends. Often paired with acute punches to form vee-shaped channels or decorative components.

Hemming Dies

Consist of a two-stage system—bending followed by flattening. Hemming dies must be precisely aligned to avoid cracking or marking the sheet.

Gooseneck-Compatible Dies

Designed with clearance in mind. When used with gooseneck punches, they support complex geometries and box-type structures.

Mult V-Dies (Multi-V Dies)

Allow multiple V-opening sizes within one die block. They increase flexibility and reduce tool changeover time.

Bottoming Dies

Used for bottom bending, where the punch forces the sheet tightly into the die angle. They improve accuracy but require more tonnage.

Beginners often assume any punch and die set will work well, but tooling quality varies significantly. High-end tools use hardened tool steel such as:

Proper heat treatment increases surface hardness, reduces wear, and prevents cracking. A poorly hardened tool may deform after only a few thousand bends, causing visible inaccuracies in parts.

Modern press brakes frequently use hydraulic or mechanical quick-clamping systems. These allow operators to:

CNC-controlled upper and lower clamping systems are especially valuable in high-mix, low-volume manufacturing, where frequent tooling changes are common.

Tooling impacts accuracy more than any other mechanical component. Inaccurate tools create:

Because tooling directly contacts the workpiece, even minor imperfections are transferred to the finished part. This is why high-quality manufacturers treat tooling as an investment, not an expense.

Achieving accurate bends is more complex than positioning a sheet and lowering the punch. The final angle results from an interplay between material behavior, tooling geometry, press-brake calibration, and operator settings. Beginners often assume bending accuracy comes entirely from the CNC system, but in reality, factors such as springback and material variability play an even larger role.

Springback is the metal’s tendency to return slightly toward its original flat shape after bending. Because the outer layers of the metal are stretched during bending, they attempt to recover once the load is removed. The amount of springback depends on:

Por exemplo:

This is why CNC systems must adjust penetration depth dynamically.

Material Variability

Even within the same batch, sheet-metal properties may differ slightly. Some sheets may have more internal stress, especially if cut by laser or sheared by a dull blade.

Tooling Wear

A worn die increases bend radius, which changes springback and angle consistency.

Backgauge Precision

If the backgauge fingers drift or deflect, the bend depth changes unpredictably.

Temperature Changes

Hydraulic systems warm up during operation, slightly altering ram behavior. High-end CNC systems compensate automatically.

Crowning Errors

Long parts tend to have inconsistent angles across the length unless crowning is properly adjusted.

Modern press brakes include one or more of the following systems:

These systems make bending more consistent and reduce operator dependency. They are especially useful for large batches or materials with high variability such as stainless steel.

The bend radius is the inner radius of the bend. Beginners often misunderstand the relationship between radius and bend quality. Larger radii produce less springback, but may require specialized punches or dies. Tighter radii increase the risk of cracking, especially in hardened materials.

The K-factor is a concept used in sheet-metal design to calculate flat patterns. It represents the location of the neutral axis during bending. Although beginners do not need to memorize formulas, understanding the concept helps explain why flat-pattern dimensions differ from simple geometry.

Modern CNC press brakes rely heavily on advanced controllers to simplify programming, reduce errors, and speed up production. Twenty years ago, operators manually calculated bend allowances and controlled only the X-axis of the backgauge. Today’s systems manage multiple axes, simulate bends in 3D, and prevent collisions before they happen.

Delem (Netherlands)

The most recognized controller brand worldwide, widely used in Europe, Asia, and the U.S. Known for:

Popular models: DA-53T, DA-58T, DA-66T, DA-69T

Cybelec (Switzerland)

Used in many European machines. Known for:

Popular models: Cybtouch 12, ModEva, Vision series

ESA (Italy)

Offers integrated systems with touchscreen interfaces. Known for:

A basic CNC press brake may have only 3 axes, while advanced machines can reach 10–18 axes.

Common axes include:

More axes provide more flexibility, especially for complicated parts.

The controller typically guides the operator through these steps:

In advanced factories, this process is partially automated through offline programming.

Press brakes serve a fundamental role in shaping modern metal products. Their influence extends across dozens of industries, from everyday household appliances to high-tech aerospace components. What makes the press brake so valuable is its ability to convert flat sheet metal into rigid, functional, load-bearing shapes with precision and repeatability. Understanding the applications helps beginners appreciate the machine’s importance and versatility.

One of the largest application categories involves electrical cabinets, control boxes, network enclosures, and telecommunication housings. These products require precise bends to create clean edges, tight tolerances, and structurally sound corners. Press brakes are ideal for producing:

Because these products rely on accurate hole alignment and perfect door fitment, press-brake precision directly impacts the overall product quality.

The HVAC industry uses press brakes to bend galvanized steel and aluminum sheets into ductwork components. These parts often involve long bends, complicated angles, and multiple return flanges. HVAC factories commonly produce:

Press brakes help reduce production cost and improve airflow performance by ensuring uniformity in duct profiles.

Press brakes play a significant role in automotive part manufacturing, especially for vehicle body structures, interior metal frames, chassis brackets, and battery enclosures in electric vehicles. Applications include:

As EV production increases, lightweight aluminum bending is becoming more important. Servo-electric press brakes are increasingly used in these applications due to their speed, low power consumption, and high precision.

Household appliances such as refrigerators, washing machines, ovens, and air purifiers use steel panels bent by press brakes. These products require smooth, scratch-free bending, making high-quality tooling essential. Press brakes contribute to:

Because appliance components typically have visible surfaces, bending finish quality is extremely important.

Architectural metal fabrication relies heavily on press brakes for producing cladding panels, decorative trims, structural reinforcements, and roofing components. Common bent products include:

Architectural applications often demand long bends—sometimes up to 6–10 meters—which is why tandem press brakes or long-bed CNC presses are widely used in this sector.

Aerospace-grade bending requires extreme precision, often within ±0.2° or better. Components must maintain exact tolerances because even small inaccuracies can affect aerodynamic performance or assembly alignment. Applications include:

Springback control is particularly important in aerospace alloys such as titanium or high-strength aluminum. These materials require specialized tooling and advanced CNC angle-correction systems.

Large agricultural machinery and construction equipment require robust steel components such as:

These components typically involve thick steel (6–20 mm or more). Heavy-duty hydraulic press brakes with high tonnage—up to 400–1000 tons—are used in such factories.

The energy sector—including solar, wind, and battery manufacturing—relies on press brakes for components such as:

As renewable energy grows, the demand for accurate sheet-metal bending continues to increase.

Press-brake safety has evolved significantly over the past two decades. In the past, operators relied solely on mechanical guards and experience. Today’s machines incorporate advanced safety electronics, laser scanners, pressure-sensitive systems, and interlocked barriers. Understanding these technologies helps beginners develop safe working habits.

Laser guarding systems are among the most common safety solutions in modern CNC press brakes. A laser transmitter projects a safety curtain in front of the punch tip. If anything—such as a hand—interrupts the beam during downward movement, the system stops the ram instantly.

Benefits include:

Popular brands include LazerSafe, DSP, and AKAS.

Light curtains are vertical arrays of infrared beams placed near the front of the machine. If a beam is broken, the machine stops. They are more affordable than laser guards but cannot operate as close to the tooling, which may reduce productivity for small parts.

Modern press brakes use safety PLCs (Programmable Logic Controllers) certified for high safety categories. These PLCs monitor sensors, interlocks, foot pedals, emergency stops, and cylinders. Redundant channels ensure safe operation even if one component fails.

Fixed or interlocked physical guards prevent operators from reaching dangerous zones near the back or sides of the machine. Sliding doors or hinged panels automatically shut down the system if opened.

Traditional mechanical press brakes required two-hand operation. Modern machines use foot pedals for ergonomic convenience, but the pedal includes:

This design ensures controlled operation.

Different materials behave differently during bending. Understanding these differences is essential for accurate results.

Mild steel is the most forgiving material. It bends smoothly with minimal cracking and moderate springback. Most beginners practice using mild steel. Common thicknesses range from 0.8 to 6 mm.

Vantagens:

Stainless steel is significantly harder and has higher springback. It requires:

Grades like 304 and 316 are common but require careful angle correction.

Aluminum is lightweight and soft, yet some alloys crack easily if bent too sharply. It has unpredictable springback—sometimes more than steel. CNC angle measurement is especially helpful when bending aluminum.

Modern industries use high-strength steels such as Q550, Q690, and AHSS. These materials require:

They are widely used for automotive crash components and structural applications.

Regular maintenance ensures stability, accuracy, and safety. Beginners often overlook maintenance, but experienced operators treat it as essential.

A clean machine reduces bending marks and eliminates contamination risks.

Regular inspections prevent unexpected downtime.

Professional technicians should carry out annual inspections for accuracy certification.

Selecting a press brake is one of the most important decisions in sheet-metal manufacturing. Buyers must evaluate not just tonnage but also accuracy, controls, lifespan, and operating costs.

Consider:

For simple brackets, a basic hydraulic press brake may suffice. For aerospace parts, an advanced CNC model is essential.

Tonnage calculation depends on:

Online calculators and CNC controllers help estimate required force.

Choose based on production needs:

| CNC Level | Suitable For | Example Features |

|---|---|---|

| Basic | Small workshops | 2D programming |

| Mid-range | OEM factories | Multi-axis control, simulation |

| High-end | Aerospace/Automotive | Laser angle correction, offline programming |

Ensure the machine supports:

Tooling compatibility affects both flexibility and long-term cost.

Servo-electric presses save energy, while hydraulic presses offer higher tonnage. Choose according to workload.

Beginners often make predictable mistakes when learning to operate press brakes. Understanding them can prevent accidents and improve part quality.

Choosing a die that is too narrow causes cracking; too wide causes inaccurate bends.

Failing to compensate causes inconsistent angles.

Incorrect positioning leads to dimensional errors.

Some beginners try to bend without checking:

This almost always causes scrap parts.

New operators sometimes overlook:

Training and awareness are essential.

Modern CNC press brakes are beginner-friendly thanks to 3D graphical programming. However, understanding materials and tooling still requires experience.

Press brakes push the metal into a die, while folding machines clamp the sheet and fold from the outside. Folder machines are more suitable for large panels.

Yes, but it requires careful tool selection and angle compensation due to springback.

High-quality tools last many years if maintained properly. Cheap tools may wear out quickly.

Compensating for springback and maintaining consistent angles across batches.

The press brake remains one of the most indispensable machines in metalworking. Whether shaping small brackets or architectural panels, whether operated manually or through advanced CNC automation, the press brake continues to define the efficiency, accuracy, and flexibility of modern fabrication. For beginners, understanding its components, bending principles, tooling, CNC systems, and safety measures provides a strong foundation for growth in the manufacturing industry.